Shortly after discovering MIG welding I also discovered TIG welding. My first TIG welder was that Hobart Stickmate welder that I attached a scratch start TIG torch to. All you need to turn any stick welder into a TIG welder is a TIG torch adapter, a TIG torch with a valve on the handle, and a tank of argon with a flow meter. The most expensive part of this was the tank of argon ($300). I bought all the rest of the parts fro around $100.

My second TIG welder was an absolute piece of crap. It was an AHP AlphaTIG. Made by the same people that make Everlast welders. They are nice welders when they run. The problem is when you need warranty support. Do your research before even considering one of these. My advice is to avoid these brands like the plague.

In 2014, I was extremely blessed to get invited to a TIG welding clinic held in Massachusetts. One of the moderators at a welding board I frequent is a master at TIG welding. He used to hold these clinics every couple of years in his shop. Turns out this one in 2014 was the last one. Man I met some amazing people. This was the only formal welding instruction I ever received. Otherwise I am completely self taught. Even in middle school shop class, Mr. Miller wasn’t much good at teaching us how to weld. He taught us how to not get burned and how to not get electrocuted and the rest was up to us.

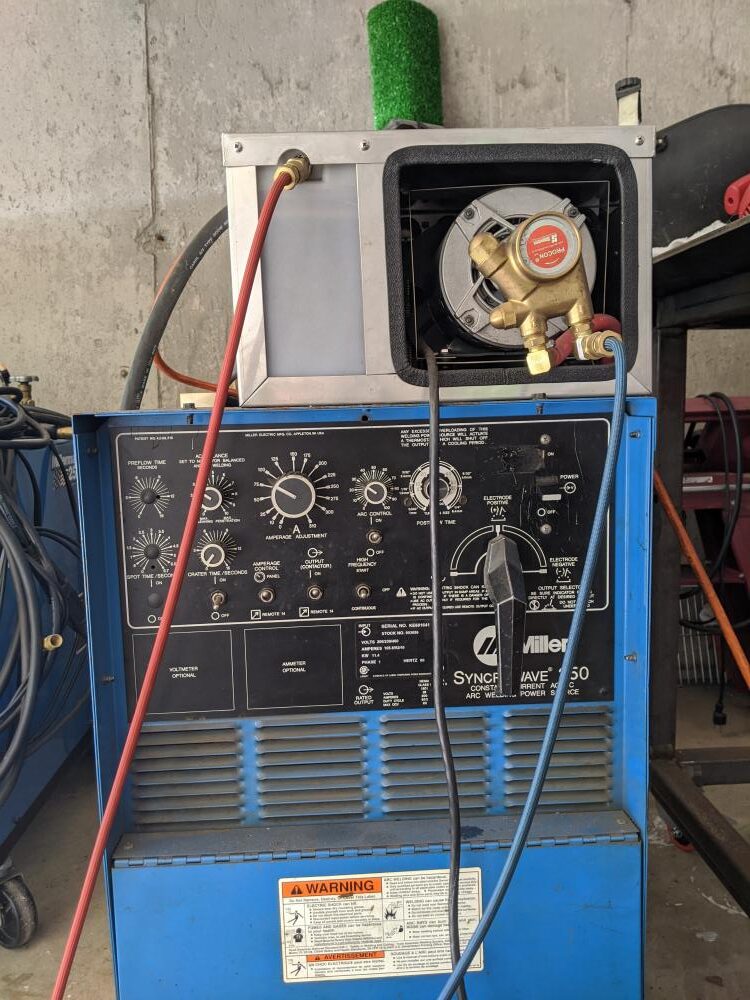

Shortly after that class I became absolutely enamored with finding a Syncrowave 250 TIG welder. I am not sure why I was in love with this particular model, but I had to have it. In 2015, I found one for sale in Craig’s List in Boston. Turns out they came out of a trade school that had closed. They guy wanted $600 each and he had three of them. But, he refused to hook them up or let me test them. I figured I would take a flyer and I offered him $900 for two. He accepted and he even loaded them into my truck with his forklift for free, which was important since they weigh 400 lbs each!

I kept one of these welders for six years, and I sold the other one. I made a heck of a profit. A short time later I found a TIG torch water cooler on Craig’s list from a fellow in Norwich that was also a major bargain. The Syncrowave 250 has a max output of 310 amps, which gets really hot. In order to not burn up your hands or your torch it is possible to buy a water cooled torch, which it turns out I really needed with this welder.

I was really determined to learn how to TIG weld aluminum. And I got pretty good at it. The problem is that aluminum, even scrap aluminum is very expensive. I could go to the scrap yard and buy steel scrap to practice with or even to build projects with for $1.00 a pound until Covid hit (it is around $2.00 a pound now). But at the time, scrap aluminum was $5.00 a pound. Just buying scrap aluminum plate to practice on was costing me hundreds of dollars.

I eventually sold this welder, as I was only really using for stick welding after a while. I refused to build things out of aluminum because of the cost. And for steel projects, I found TIG welding to be too slow and unwieldy as compared to MIG welding. In 2021, Lee-Ann bought me a new welder for father’s day, my current Multimatic 255. That welder is also a DC TIG welder. My foot pedal, water cooled torch and my water cooler all found a new home on the Multimatic, and the Sycrowave was sold to a good home. Now if I need to weld aluminum, I will just MIG weld it.