About the same time that I purchased my Hobart Stickmate welder, I came to realize there are a number of different electric arc welding processes. The big three that most hobbyists use are stick welding (Shielded Metal Arc or SMAW), Metal Inert Gas (MIG) and Tungsten Inert Gas (TIG). I grew up with stick welding, and had previously never heard of the others. Stick, just like it sounds, is where the stick electrode is energized and you strike an arc, and the electrode is also the filler metal.

TIG welding which I briefly described in my last post is a two handed welding process. You hold the torch in one hand, and you feed in filler wire with the other hand. With TIG welding the electricity is not delivered to the arc through the filler wire. Rather the torch uses a non consumable tungsten electrode to make the arc. Originally called “heliarc” welding, TIG welding has its roots in aerospace manufacturing and was used to new, esoteric alloys like aluminum and titanium. These days TIG welding is used by hobbyists mostly where aesthetics matter, or in thinner metals, like auto body work.

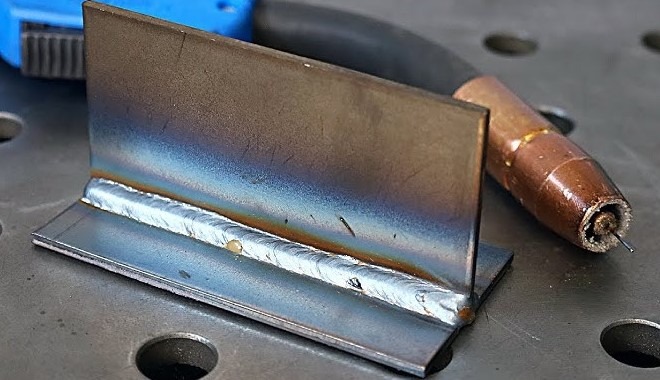

MIG welding is different because it feeds a continuous wire into the weld pool and the electricity for the arc is delivered through the same wire. All MIG welders deliver wire through a roll of wire in a wire feeder that is usually integral to the welding machine. This wire is fed into the weld puddle through a “gun” that has a trigger on it to activate the process. You can think of this as an electric glue gun for metal. It is a very efficient and productive process and can be done one handed, which makes it great for hobby welders, freeing up the other hand to hold parts together for welding.

To me, wire feed welding (MIG as well as the related flux core wire welding) is basically the perfect welding process, and has become my favorite. You can use MIG for all metal thicknesses, and may metal types (aluminum, stainless steel and mild steel). Over the last 10 years or so I have owned a number of different stick, MIG and TIG welders, and often has all three types at once. But now my one and only welder is a wire feed welder.

My first MIG welder was a Hobart Handler 190. It was a REALLY great welder and I recommend it to anyone. I welded a lot of stuff with this machine, but it had its limitations. Mostly it was really only good for metal up to 3/16ths of an inch in thickness. That’s not a fault of the machine per se, its just that’s about the max you can weld with 190 amps. And if you know me, you know bigger is always better.

My next MIG welder was a BEAST (300 amps max). Its a Millermatic 252 that I found on Craig’s List (in NJ of all places) for $1500. That was a massive bargain! I really loved that machine. It was nearly perfect. I used it to run dual shield flux core wire on thick steel and it welded like a dream. But in 2021 I started to learn about pulsed MIG welding (or more accurately pulsed spray MIG welding), and like a car with more horsepower, I just had to have it.

My current welder is a Miller Multimatic 255. Technically it is a MIG welder, a TIG welder, and stick welder, all in one. But in reality, it will only TIG weld steel (DC welding only) and while it is a really great stick welder, I hardly use it for anything but wire feed welding. Where as all my other welders were transformer welders (i.e., dumb welders), this is my first inverter welder (i.e., computer controlled). I actually recently updated the software in this welder which added new features. I think I am a fan of the computerized welders, which is good because most new welders these days are inverters. They are lighter, more efficient and can pack in a lot more specialized features than a transformer welder.

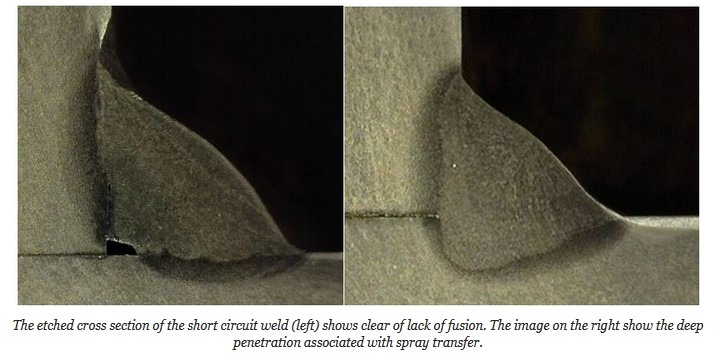

One unique feature of this welder is its ability to do pulse MIG welding. There are not a lot of machines on the market that can do this yet.

I like having the ability to use pulsed spray transfer to be sure my welds are top notch. So next time I am building a tank or a battleship, I know it will stick together. 😁